Since the introduction of its nuclear pressurizer heater in 1966, Watlow has been a major source for designers and contractors who specialize in serving the nuclear power industry. For over fifty years, it’s been the Watlow name behind many of the critical application heaters used in our industry.

Today, facility managers who face obsolescence can get like-for-like replacement parts with the same premium design, construction, and performance of the Watlow originals - and from a proven, trusted partner who can bring decades of experience and know-how to your project.

For critical application heaters and Watlow trusted design, your new source is NuSource.

Today, facility managers who face obsolescence can get like-for-like replacement parts with the same premium design, construction, and performance of the Watlow originals - and from a proven, trusted partner who can bring decades of experience and know-how to your project.

For critical application heaters and Watlow trusted design, your new source is NuSource.

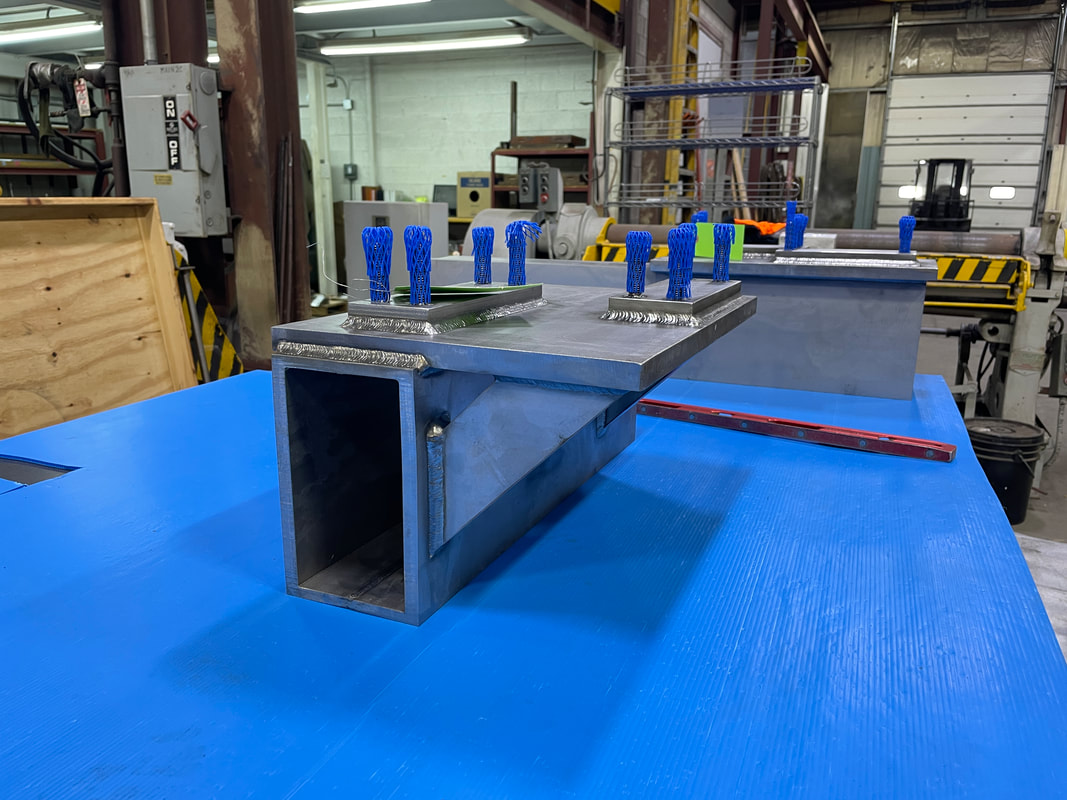

EDG Immersion Heaters

|

Emergency Diesel Generator

Immersion Heaters

Features

|

|

Pressurizer Heater

|

ASME Section III, NPT stamped

Pressurizer Heaters

Features

|

|

PRODUCTS OFFERED

|