Supplying the nuclear industry with

|

NuSource supplies safety-related hardware solutions to the nuclear power industry. We specialize in difficult-to-solve replacement solutions that are critical to plant operation and regulatory compliance. For every project, NuSource delivers the engineering expertise, the nuclear industry knowledge, and the manufacturing skills needed to supply the solution that best meets all of the customer, plant, code, project, and documentation requirements.

CAPABILITIES

Fabrication

|

Our fabrication capabilities include ASME code, instrumentation & control, and close tolerance CNC machining. All facilities operate to the applicable nuclear safety-related quality requirements, including ASME Section III, NQA-1 and 1 0 CFR 50 Appendix B.

ASME Boiler and Pressure Vessel Code Section III Hardware

Safety-Related Instrumentation & Controls and Electronics

Safety-Related CNC Machining

|

ASME Boiler and Pressure Vessel Code Section III Hardware

NuSource is an excellent partner for projects that include outage hardware, custom replacements, and specialty repairs.

Safety-Related CNC Machining

|

Engineering

|

NuSource engineering staff has decades of experience working in the nuclear industry, including leading major industry and regulatory initiatives that impact the supply of safety-related replacement hardware. Our company integrates engineers from member-company MPR Associates to provide expert staff for all engineering deliverables.

Features

|

|

NuSource engineers are involved with each phase of every NuSource project. Our engineering-first approach begins well before a project is awarded, often when the value of NuSource can be leveraged most. Our engineers work with the customer to ensure that all code, design, licensing, and project requirements can be satisfied and can be realized. This interaction between our engineering and manufacturing organizations reduces project risks and mitigates negative impacts to design, fabrication, budget, and project schedule.

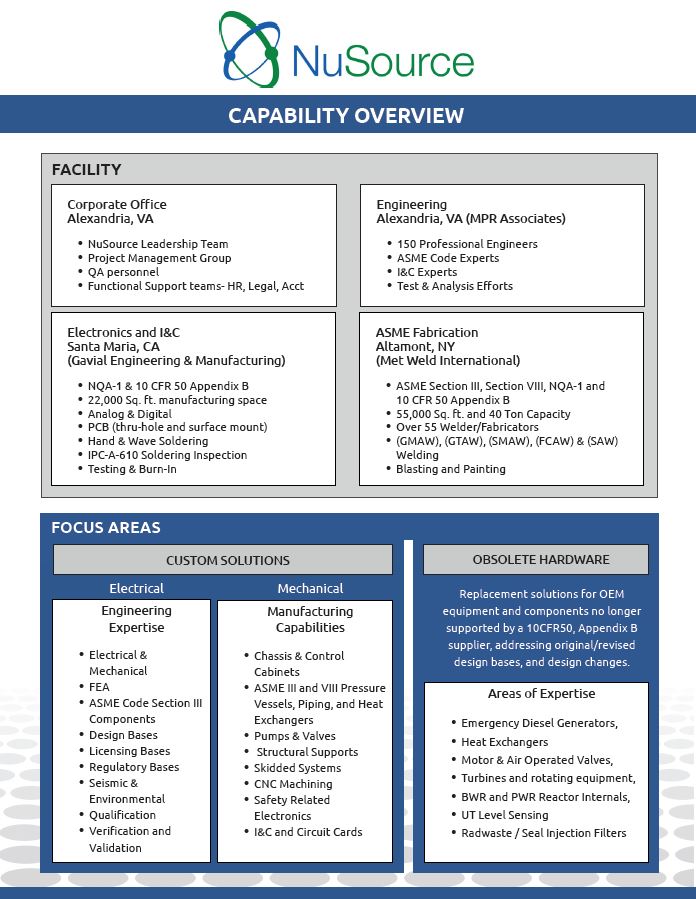

Facilities

|

NuSource is headquartered in the Old Town district of Alexandria, Virginia. Alexandria is home to NuSource’s management team, project management group, and engineering staff. Manufacturing work is performed at facilities in Santa Maria, CA (I&C), and Altamont, NY (ASME Code fabrication).

Corporate Office

Alexandria, VA

Engineering

MPR Associates | Alexandria, VA

ASME Fabrication

Met Weld International | Altamont, NY

Electronics and I&C

Gavial Engineering | Santa Maria, CA

|

NuSource maintains full control of all engineering and manufacturing efforts. We utilize our member companies, MPR Associates and Gavial Holdings, as well as and other strategic partnerships for manufacturing-critical services. Work is performed at manufacturing facilities in Santa Maria, CA (I&C) and Altamont, NY (ASME code fabrication).

|

PROJECT HIGHLIGHTS

NuSource fabrication treats each project with the attention and care of any first-of-a-kind project. This culture makes NuSource an excellent partner for projects that include outage hardware, custom replacements, and specialty repairs.

|

Design, Manufacture and Testing of ASME Section III Cavitating Venturis.

|

NuSource Fabricates Nine New Emergency Feedwater Air Accumulators

|

|

The cavitating venturis are being added to the Emergency Feedwater System (EF) as a safety feature to prevent pump run out and ensure flow to the steam generators. The project was completed in accordance with the NuSource Quality Assurance Manual via its N stamp and Appendix B nuclear program.

READ THE FULL STORY ON LINKEDIN |

The safety related (Appendix B) pressure vessels range in sizes from 51" diameter x 15 ft. long to 10ft. diameter x 16ft. long and were designed and fabricated on an expedited schedule.

|

OEM TEAMING PARTNERS

“Like-for-Like” replacement parts based on original design information and quality standards.

NuSource combines the resources of MPR Associates and Gavial Holdings to bring you more than 50 years of engineering experience and 35 years of manufacturing in providing safety-related Appendix B parts and services.