A DEEP HISTORY, PROVEN WORKMANSHIP, FULLY ACCREDITED

-

WHO WE ARE

-

WHAT WE DO

-

WHY IT MATTERS

<

>

A TEAM OF OVER 400 EMPLOYEES POSITIONED IN FOUR LOCATIONS THROUGHOUT THE US THAT HAS SUCCESSFULLY DELIVERED PROJECTS TO EVERY NUCLEAR POWER PLANT IN THE UNITED STATES AND CANADA.

LEADERSHIP TEAM

MARK VARNO

PRESIDENT

PRESIDENT

Mark has 40 years of experience and success leading business operations and engineering organizations in the commercial nuclear power industry. His diverse perspectives are molded from leading multiple OEM nuclear services businesses, as a senior leader at operating nuclear power plants, and leading consulting services companies in the nuclear industry. Mark is a proven leader with a client centric approach and commitment to deliver high-value solutions to global nuclear customers.

PATRICK BUTLER

CHIEF TECHNICAL OFFICER

CHIEF TECHNICAL OFFICER

Patrick is a 37-year veteran of MPR Associates, Inc with extensive leadership experience in nuclear plant design engineering and project management for global clients. Patrick has led the design and delivery of numerous hardware and tooling solutions for complicated industry issues ranging from Three Mile Island recovery, BWR Shroud repairs, and a multitude of component solutions saving utilities costly system modifications. He is a registered PE and an active participant on the ASME Executive Committee.

WAYLON WATERS

DIRECTOR OF BUSINESS DEVELOPMENT

DIRECTOR OF BUSINESS DEVELOPMENT

Waylon has over 22 years of Sales and Business Development experience with a focus on delivering custom designed and fabricated components for commercial nuclear power facilities. His extensive fabrication knowledge compliments his business development and sales acumen to deliver cost effective solutions for customers. Waylon provides the strategic leadership for customer relationship development, growth plans, and OEM Partnerships.

BRETT MCGLONE

QUALITY ASSURANCE MANAGER

QUALITY ASSURANCE MANAGER

Brett has over 20 years of diverse experience and successes in the nuclear power industry. His experience includes developing and leading nuclear quality assurance program for a valve manufacturer, serving as an operator in the US Navy Nuclear Program, and as an Authorized Nuclear Inspector. Brett possesses extensive ASME Code knowledge is actively participating in various ASME Code Committees in leadership roles.

BEN FRAZIER

ENGINEERING MANAGER

ENGINEERING MANAGER

Ben has over 20 years of nuclear experience including as an Officer in the US Nuclear Navy Program and engineering leadership roles at MPR Associates, Inc. He has performed and managed engineering activities focused on the design, analysis, fabrication, and testing of components for nuclear power plants. Work has been performed for over 30 U.S. nuclear power plants and multiple U.S. and international fabrication companies. Ben is a registered Professional Engineer.

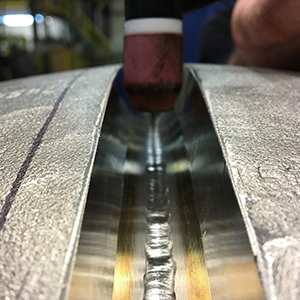

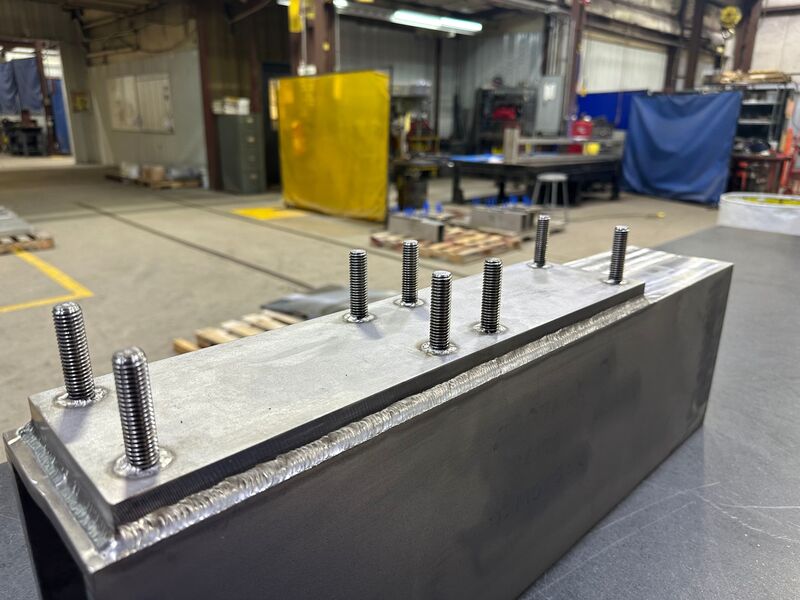

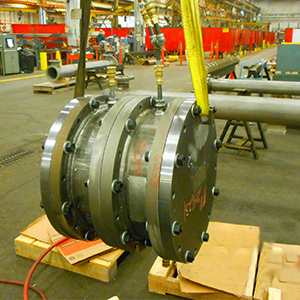

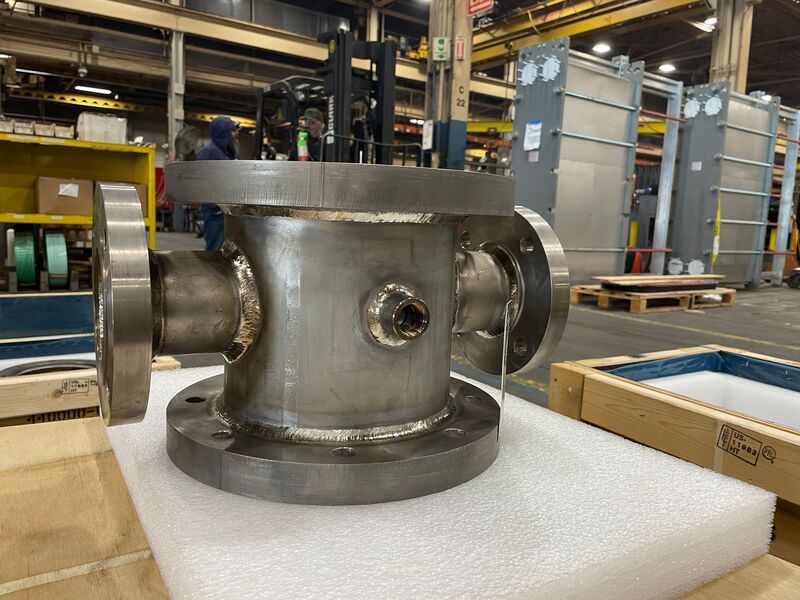

TURN-KEY DESIGN AND BUILD, FABRICATION, WELDING, MACHINING, AND REVERSE ENGINEERING; EXCLUSIVELY FOR THE NUCLEAR POWER INDUSTRY.

NuSource supplies safety-related hardware solutions to the nuclear power industry. We specialize in difficult-to-solve replacement solutions that are critical to plant operation and regulatory compliance. For every project, NuSource delivers the engineering expertise, the nuclear industry knowledge, and the manufacturing skills needed to supply the solution that best meets all of the customer, plant, code, project, and documentation requirements.

OFFERING A HIGH LEVEL OF ENGINEERING EXPERTISE, DESIGN, AND PROJECT MANAGEMENT KNOW-HOW WITH PROVEN EXPERIENCE IN NUCLEAR FABRICATION.

With the combined resources of MPR Associates and Gavial Holdings, we bring more than 50 years of engineering experience and over 35 years of manufacturing experience to the business of providing safety-related Appendix B parts and services to nuclear customers. You can count on us to:

- Understand ASME Code, 1 0 CFR 50 Appendix B and plant-specific design and licensing basis requirements such that design inputs are appropriately factored into every NuSource solution.

- Know our customers' expectations regarding safety culture and quality and ensuring they are met.

- Consider the implications of plant design change processes and factoring those processes into every NuSource solution.

- Review plant and equipment operating experience and factoring that experience into the equipment specification to maximize the functionality and life of the equipment.

The NuSource quality assurance program meets the requirements of ASME Section III and 10 CFR 50 Appendix B.

ABOUT OUR QUALITY ASSURANCE PROGRAM

ABOUT OUR QUALITY ASSURANCE PROGRAM