Supplying the nuclear industry with specialty equipment,

|

|

April 2012 QA Program EstablishedNuSource quality assurance program meets the requirements of ASME Section III and 10 CFR 50 Appendix B. July 2013 October 2013 August 2015 November 2015 September 2016 March 2018 July 2018 April 2019 February 2020 |

vertical divider

NuSource supplies safety-related hardware solutions to the nuclear power industry.

A singular focus.

Our only business is to provide safety-related equipment to commercial nuclear power plants, NSSS providers and major OEM’s that also support the industry.

We are NUPIC and NIAC audited, offering a level of engineering expertise and accreditation that few organizations possess and most fabrication vendors do not possess. And with partners operating in four locations throughout North America, NuSource can provide solutions in every nuclear discipline including welding, machined components, reverse engineering, project management and compliance. We understand the various constraints that plants face when procuring and installing replacement nuclear hardware. No matter the scope, size or location, NuSource clients can trust in on-time delivery of products that are designed and manufactured correctly and with the appropriate amount of oversight and testing.

NuSource has completed successful projects in every nuclear power plant in the United States and Canada.Industry DemandsA 2014 report published by the Institute of Nuclear Power Operations (INPO) identified critical performance gaps and challenged nuclear utilities to demand more of their suppliers. Specifically, the INPO asked for increased rigor in testing, better engineering documentation, and more manufacturing integration.

NuSource is aligned squarely behind those recommendations with the following commitments to our clients and the industry:

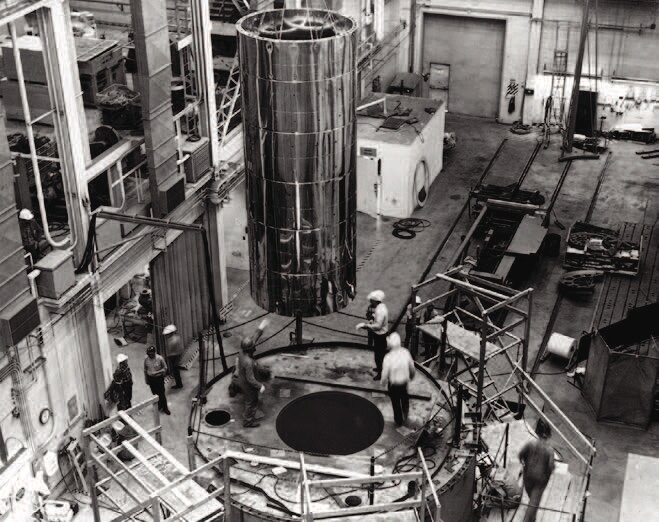

DEC 2016 - NuSource designs and manufactures (9) safety related Emergency Feedwater Air Accumulators

NuSource has been contracted to provide (9) new air accumulator pressure vessels as part of a modification to provide backup compressed air to operate critical feedwater air operated control valves. The safety related (Appendix B) pressure vessels range in sizes from 51" diameter x 15 ft. long to 10ft. diameter x 16ft. long and were designed and fabricated on an expedited schedule to meet the client’s needs. NuSource successfully provided the components on an expedited delivery while also meeting, and exceeding all quality, craftsmanship and documentation requirements. For every project, NuSource delivers the engineering expertise, the nuclear industry knowledge, and the manufacturing skills needed to supply the solution that best meets all of the customer, plant, code, project, and documentation requirements. This project was performed in accordance with the NuSource Quality Assurance Manual via its Appendix B nuclear program.

JUNE 2018 - Safety-Related Control Air (NIAS) Pall After-Filters

Through its exclusive partnership with Pall Corporation for nuclear aftermarket spares, NuSource provided Control Air (NIAS) After-Filters to a Boiling Water Reactor plant in the Midwest. Check out the full story here.

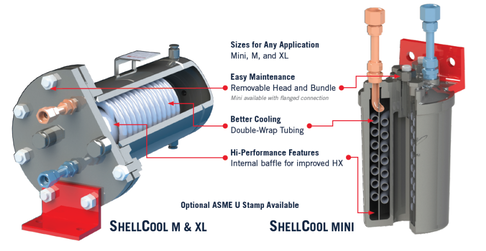

March 2021 - NuSource becomes the exclusive provider of the Flexaseal ShellCool water-cooled heat exchanger system. This system is essential for nuclear power plants to meet temperature limitations for sealing elements that are critical to the efficiency and safety of the pumps and other vital parts.

|